Written by: Emmad Rehman

As I reflect on my journey with Falcon Engineering, I can’t help but feel a profound sense of gratitude. As a fresh graduate, with no prior experience in my field, I was nervous to begin a new chapter of my life at Falcon Engineering. However, over the past year and a half, I have felt nothing but privilege and pride to be working in an organization that truly values each and every one of its employees. The friendly company culture, and open-office environment, encourage collaboration among colleagues.

From the moment I joined the team, I could sense the positive energy and the emphasis on building strong relationships. The Principals at Falcon Engineering in Kelowna understand the significance of creating a supportive and inclusive environment. By fostering a culture of trust and respect, they have laid the foundation for a motivated and engaged team.

One of the key aspects of Falcon Engineering’s culture is its open-office environment. This eliminates hierarchical barriers and encourages open communication throughout the organization. From Principals to Jr. Engineers, everyone is accessible and approachable. This accessibility not only allows for a natural flow and exchange of ideas but also facilitates mentorship and growth opportunities for all team members. Knowing that I can approach anyone, regardless of their position, has been invaluable in my professional development. Moreover, at Falcon Engineering, there is no shortage of lively discussions and brainstorming sessions. What sets these conversations apart is the active participation of all team members. Regardless of role or tenure, everyone’s input is valued. This collaborative approach not only brings diverse perspectives to the table but also fosters a sense of ownership and collective responsibility. It is empowering to have the opportunity to contribute to the company’s overall growth.

In an era where micromanagement can limit creativity and productivity, Falcon Engineering takes a refreshing approach. The mechanical, electrical and energy engineering Principals understand the importance of giving employees autonomy and trust to do their best work. Rather than hovering over every detail, they focus on providing guidance, setting clear goals, and supporting individuals to achieve their objectives. This macro-management style not only cultivates a sense of ownership but also allows for innovation and professional growth.

Perhaps the most remarkable aspect of working at Falcon Engineering is the comfortable work atmosphere that allows for a stronger team bond. From day one, I was greeted with warmth and kindness, and it didn’t take long for me to feel like part of the Falcon Engineering family. Beyond professional achievements, Falcon Engineering genuinely cares about the well-being of its employees. Whether it’s through team-building activities, lunch and learns, or simply taking the time to inquire about each other’s health and well-being, the team at Falcon Engineering truly demonstrates a commitment to the overall development and well-being of its people.

All in all, joining Falcon Engineering has been a transformative experience for me. From the welcoming company culture and family-like atmosphere to the endless opportunities for growth and development, Falcon has created an environment where everyone feels valued and empowered. Falcon’s emphasis on macro management has fostered a culture of trust, autonomy, and collaboration, allowing all employees to thrive both individually and collectively as a team. As I continue my journey with Falcon Engineering, I am grateful for the supportive community I am part of and excited about the opportunities that lie ahead.

Want to learn more about our mechanical, electrical and energy engineering services? Visit our engineering services page or contact us today.

Check out some of our other blogs to learn more about our Kelowna engineering company:

- Falcon Engineering is Climate Neutral Certified

- Benefits of Troubleshooting your HVAC System

- Falcon in the Community

Aging fire protection systems can be subject to catastrophic failures which require emergency funding. Constant monitoring, inspections, and proper maintenance can provide advanced warning of system problems, so that any upgrades needed can be initiated in a thoughtful and careful manner at a reduced capital cost.

Engineering analysis will help guide the process of deciding whether to allocate capital funds for replacement or continue with the current maintenance program.

As we established in our earlier blog Elements of a Fire Sprinkler System, there are a number of different sprinkler systems, including wet and dry systems. Dry systems don’t contain water and are pressurized with air, while wet systems have pipes filled with pressurized water at all times. Both systems can experience issues as they age.

Below, we discuss the top 11 items to look for with aging sprinkler systems:

1. Inspection Testing and Maintenance

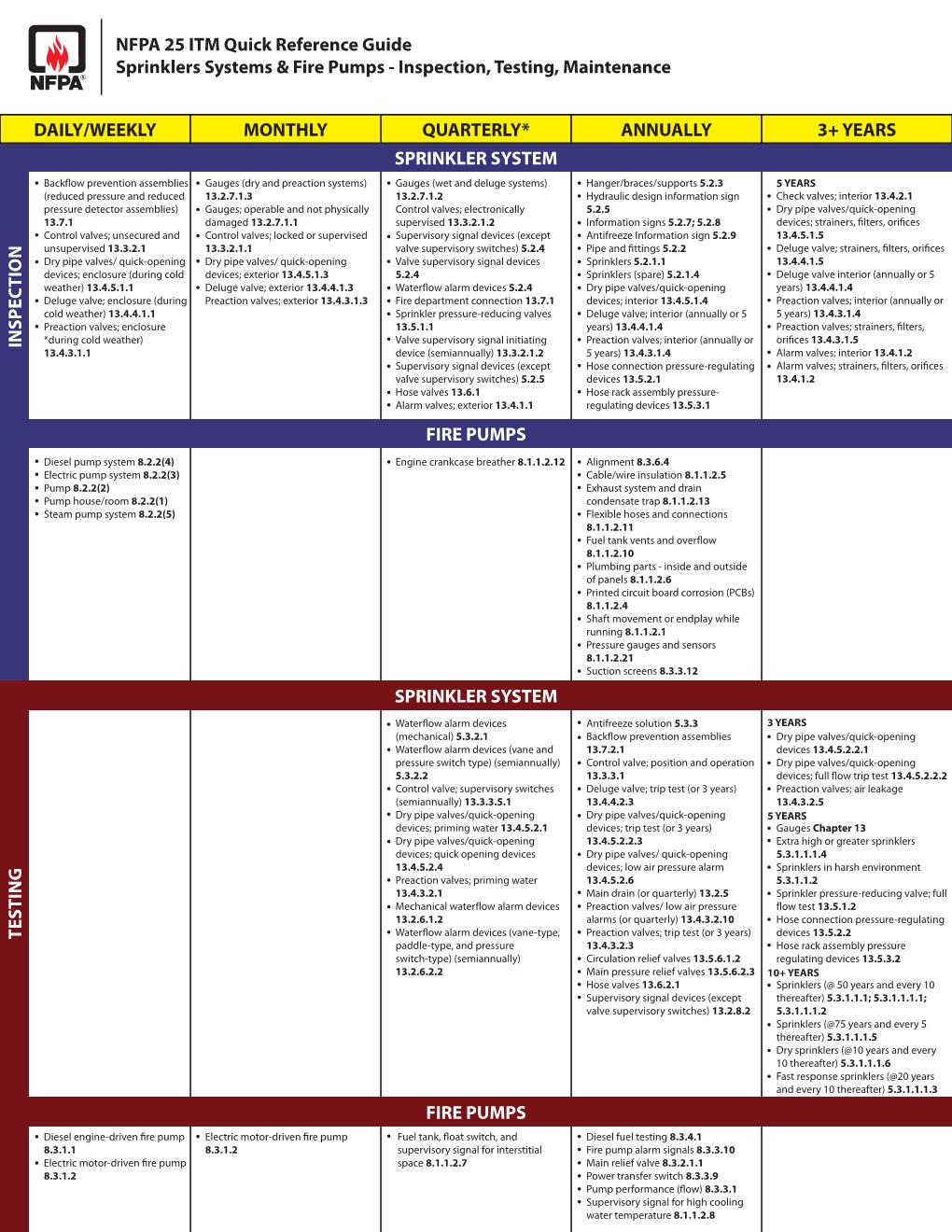

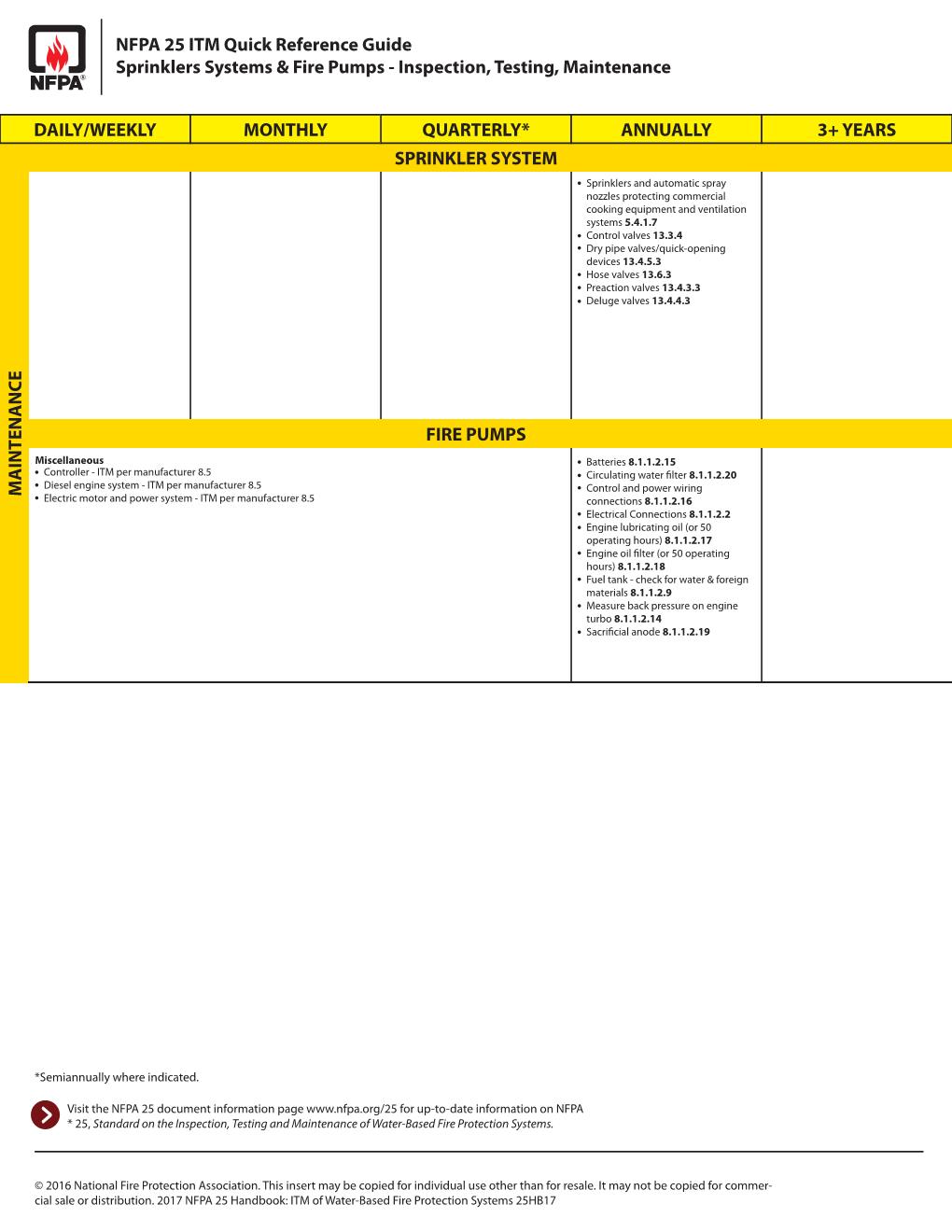

The National Fire Protection Association (NFPA) 25 standard governs the inspection, testing and maintenance of water-based fire suppression systems, and gives timelines for what should be covered in quarterly, semi-annual, annual, three-year and five-year inspections. The required inspection reports should be completed by a competent and careful service provider as required by NFPA 25. The NFPA 25 chart is included at the end of this blog.

2. Dry Systems

Typically, dry systems degrade much faster than wet systems due to increased levels of oxygen, and require special care and attention, especially for systems that are older than 20 years which may be nearing the end of their service life. In unusual circumstances, we have seen dry system pipes fail in as little as 2 years. Additional measures, such as the introduction of nitrogen into dry systems, can extend a dry system’s life expectancy considerably.

3. Leaks Developing in Pipe

Keep an eye out for external seepage. Pipes rust from the inside out, so if you can see signs of seepage on pin holes or threads, you will need to react quickly.

4. Dry System Air Compressor Runs Continuously

A dry system air compressor should only run every 2 or 3 days. If it runs more often, you have leaks. One of the biggest problems is that as more compressed air enters the pipe, more moisture and oxygen is introduced, and so more corrosion occurs. It is a vicious cycle.

5. Recalled Sprinkler Heads

Many sprinkler heads manufactured by Central were recalled in 2002 because the seal would stay plugged which wouldn’t allow water through when activated. This could result in the loss of a building if there was a fire. We still see these heads in facilities, together with many other heads that have also been recalled. Visual inspections by a trained eye are the best solution.

6. Renovations without Checking System Design

Alterations to a sprinkler system may stop the system from operating properly with the city water pressure. Simply adding or relocating one sprinkler head in the design area could place the owner at risk if the system is not compliant with NFPA 13. NFPA 13 is the standard for the installation of sprinkler systems, which provides minimum requirements for the design and installation of automatic fire sprinkler systems and exposure protection sprinkler systems.

7. Destructively Tested

Sprinkler heads need to be destructively tested to be compliant with NFPA 13. This test is conducted by an approved laboratory to ensure a representative sample of the sprinkler heads installed will activate properly when heated to the listing temperature. At the end of the service lengths listed below, four heads of each style need to be removed and tested:

50 years – Standard Heads

20 years – Quick Response

10 years – Dry Heads

If a single head fails, all similar heads on site will require replacement.

8. Know How to Turn Off a Sprinkler Zone in an Emergency

In the event of an accidental discharge through a sprinkler head or a broken sprinkler pipe, the quick identification and location of important sprinkler valves will mitigate the potential for significant water damage.

9. Building Envelope

We have seen a lot of building envelope issues that have led to wet sprinkler pipe freezing. The sprinkler heads can pop or the pipes break during cold weather spells. When the water in the sprinkler system thaws, the water flows can be significant, and trigger unexpected facility evacuations. Recent renovations completed in the summer are a common source of these events.

10. Drain Maintenance

If dry systems are drained of water in the fall before the cold season, then the potential for the sprinkler pipe freezing is minimal. If it takes a long time to drain a system, the rust inside the pipe might be retaining water and slowing down the process. This may indicate a requirement for an internal inspection.

11. Water Sequence Entry Pipe Comes Apart

We have seen some services that use galvanized or plated rods in a high water table, which accelerate the corrosion on the threads, and come apart with catastrophic flooding. Modern practices using stainless steel rods and better thrust blocks help to improve reliability and longevity.

Conclusion

Throwing good money at a bad system is not typically the best long term solution. 35 years for a wet system and 25 years for a dry system is a common life expectancy. But the reality is that the life expectancy will depend on the water chemistry, materials used in the system, and a proper maintenance program.

The NFPA 25 chart below lists the minimum required frequency for inspection, testing and maintenance activities.

At Falcon Engineering, we can help with identifying any potential issues with aging sprinkler systems and work with our clients to find solutions. If you have any questions about how our team can help you with your mechanical projects, including fire sprinkler engineering, get in contact by using our contact page.

Want to learn more about our engineering services? Visit our mechanical engineering services page.

Want to learn more about engineering? Check out some of our other blogs!

- Integrating Renewable Energy: A Clean Energy Revolution

- How HVAC Design Can Ensure Comfort and Energy Efficiency

- Dogwood Auditorium: An Innovative Geoexchange Design

We will be discussing why radon testing is needed in our schools and universities, how to test these buildings for radon and steps to take if high levels are found.

Why Radon Testing is Important

With increased radon testing being completed in British Columbia, the extent of the radon problem in our province is becoming clearer. The need for radon testing in schools and universities is abundantly evident. In many Interior BC Communities, greater than 30% of the residences tested exceed the Health Canada Radon Guideline of 200 Bq/m3. The BC Centre for Disease Control Interactive Map is a valuable resource that compiles radon testing data and shows recorded radon levels for regions and municipalities across the province.

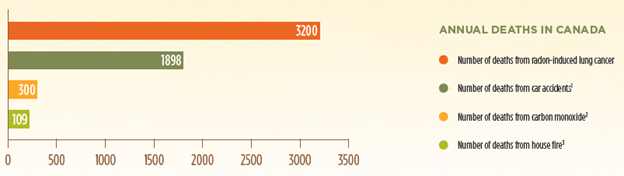

Radon is the leading cause of lung cancer in non-smokers. It is responsible for more deaths in Canada each year than car accidents, carbon monoxide poisoning, and house fires combined.

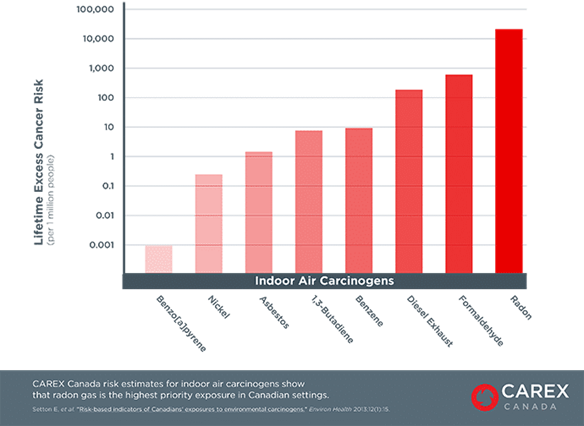

According to CAREX Canada, a multi-institution research team hosted at the University of British Columbia, risk estimates for indoor air carcinogens show that radon gas is the highest priority exposure in Canadian environmental settings. The lifetime excess cancer risk is more than 10,000 times greater for radon than asbestos.

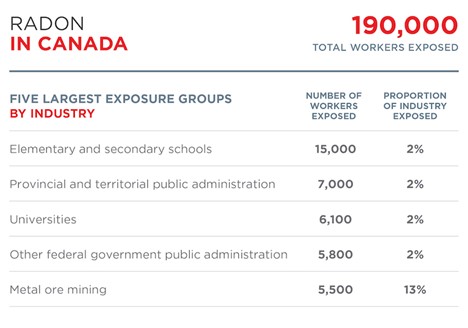

Over the past few years there has been a significant push to improve awareness for the need to test radon in our homes. However, to reduce overall lifetime exposure, there needs to be a focus on other places where people spend significant amounts of time, such as our workplaces and schools. According to CAREX Canada, around 190,000 Canadian workers are exposed to radon levels above Health Canada’s guideline of 200 Bq/m3. The industries with the highest rates of workplace exposure include elementary and secondary schools, provincial and territorial public administration, and universities. It’s worth noting that these figures include workers only and do not take into account the exposure of students or visitors to these locations.

In schools and universities, the number of students far exceeds the number of staff, making these buildings an even higher priority for radon testing. In addition, radiation exposure from radon while we are young can have increased harmful health effects. This makes it even more important to take action to minimize radon exposure in infants, children and youth. The Evict Radon website describes why young people are more vulnerable to radon gas exposure:

- Children have still-developing organs. Rapidly growing tissues and cells are very vulnerable to DNA damage from radiation exposure, as their DNA is being replicated. Any resulting genetic mutations can be propagated to all cells arising from the damaged cell.

- Children weigh less, and so their overall exposure (i.e. the amount of radon they absorb per kilogram of body mass) is much greater compared to an adult.

- Children breathe faster. An infant or small child will respire 2-3 times faster than adults as they have little lungs and are often more active. Faster breathing means more radon exposure.

- Children have more life left. Radon exposure causes DNA damage and genetic mutations that may take 10-30 years before lung cancer is diagnosed. Early life radon exposure means a person is more likely to live long enough to get cancer from it.

In terms of lifetime relative risk of developing lung cancer, a child exposed to 1,000 Bq/m3 radon from birth to their 6th birthday (5 years) has already inhaled the equivalent of a lifetime breathing in air with 200 Bq/m3 radon.

Radon Testing in Schools and Universities

The only way to know if a building has a high radon level is to test. Radon is invisible, odourless, tasteless and leaves no trace. Concentrations observed are specific to each building and specific areas of a building. It has been observed, over several instances, where one building has radon levels 20-30 times greater than the Health Canada Guideline while neighbouring buildings are well below the guideline. In schools, universities, and other public buildings, radon levels can vary significantly from building to building, section to section, and even room to room.

It is recommended to test all rooms that are occupied for 4 or more hours each day that have direct contact with the ground or a crawlspace. On upper levels, occupied rooms should be included in the testing if a room directly below it is not being tested.

Radon levels can change significantly over time and vary daily and seasonally, within a building. It is not unusual for radon levels to fluctuate by a factor of 2 to 3 over the course of a day, and variations between seasons can be even greater. Health Canada recommends a minimum three-month long-term measurement during the winter heating season when doors and windows are predominantly closed and there is a lower likelihood for outside air to dilute the indoor gasses. It is best to avoid carrying out long-term measurements during spring and fall if increased ventilation volumes are used as low-cost cooling in the building (i.e., economizing) as this can skew the results.

Health Canada recommends a C-NRPP Measurement Professional be involved in the measurement strategy and implementation of radon testing. More information on radon test placement and quality assurance measures can be found in Health Canada’s Guide for Radon Measurements in Public Buildings.

Alpha track devices are the most common technique for radon measurement. They are comprised of a small piece of bulletproof plastic enclosed in a plastic housing. The radiation from radon creates small scratches and pit marks in the bulletproof plastic. After a minimum of 90 days, it is sent to a lab for analysis. The device does not contain any harmful substances and is completely safe to be around children.

Buildings should be retested whenever major renovations are undertaken or there is an alteration of the ventilation or airflow within a building.

If the long-term radon test shows elevated radon levels, the first step is often to conduct short-term digital radon testing to determine if radon levels are elevated during occupied periods. Ventilation can help to lower radon levels during occupied periods, which reduces the radon exposure when people occupy the building. The average radon level measured on a long-term test may not be representative of the radon concentration when staff and students are present. Short-term radon testing completed with a digital continuous radon monitor can measure radon levels on an hourly basis. This allows the effect of the ventilation system to be determined, and the estimated long-term radon levels during occupied periods to be calculated.

Radon Mitigation in Schools and Universities

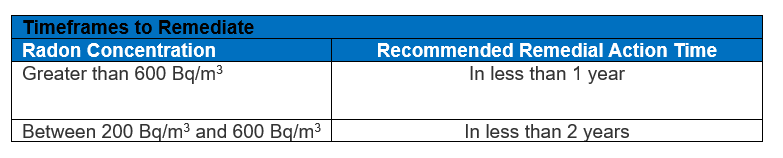

Radon concentrations can vary year-to-year and season-to-season. Health Canada recommends that mitigation still be considered when levels are below but approaching 200 Bq/m3. When long-term measurement results are over 600 Bq/m3, mitigations are recommended within the timeframe identified below based on the Guide for Radon Measurements in Public Buildings.

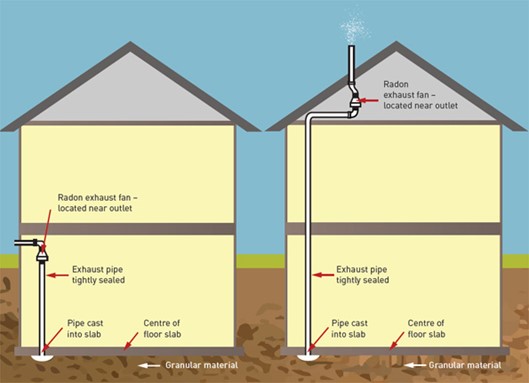

The two most common methods to lower radon levels in a school environment are increased ventilation, or the installation of an active soil depressurization radon mitigation system (ASD). An active soil depressurization system directly targets radon gas by minimizing the amount that enters the building. Ventilation dilutes radon by replacing some of the air in the space with low-radon outdoor air.

An active soil depressurization system works by creating a negative pressure zone beneath the building’s foundation or slab. This negative pressure pulls the radon gas into the radon piping system, discharges it to the atmosphere and prevents the radon from entering the building. To install a soil depressurization system, a hole (typically 5-7” in diameter) is cored through the foundation or slab, and a suction pit is created. A pipe with an inline fan is then installed so that it pulls air from the suction pit and vents it outside the building. The air and radon gas are then vented outside the building. Depending on the area of coverage needed, porosity of the sub slab material and building pressures, multiple suction points may be required for effective radon mitigation.

Sealing gaps and cracks in the foundation alone is typically not sufficient to reduce radon to acceptable levels. Because radon is pressure driven, even if all the visible cracks are sealed, there will be small entry points that allow radon gas to enter the building. However, for an ASD system to work effectively, the foundation must be well-sealed. The ASD system works by creating a pressure differential between the soil beneath the foundation and the indoor space. Cracks and gaps in the foundation reduce the pressure differential that can be achieved across the slab, resulting in the need for more suction points and higher-powered fans. With large gaps or numerous cracks, the system can’t achieve a sufficient pressure differential to reduce the radon gas infiltration into the building. If the foundation is a dirt crawlspace, it can be sealed with a poly membrane before an ASD is installed.

The following are key considerations when determining the most appropriate radon reduction method for a building:

- Radon levels

- Number and location of rooms with high radon levels

- Building design and foundation type

- Mechanical systems and ease of adding additional ventilation

- Relative pressures within the space

- Porosity of sub-slab material

- Installation cost

- Energy efficiency and operating cost

- Reliability

While both ventilation and ASD systems use energy to operate, an ASD system usually requires significantly less energy than a ventilation system. The increased ventilation flow rate required for effective lower radon levels in a space is typically much larger than the air moving through an ASD system. The majority of the cost associated with ventilation is energy required to heat or cool the outdoor air before it is introduced into the space.

A dedicated radon mitigation system, such as ASD, may be more reliable at reducing radon levels in the long term. A risk to using ventilation systems to control radon is how the ventilation control system can be altered relatively easily. There are examples of situations where staff, particularly new staff, who are not aware of the ventilation strategy objectives, lower the ventilation rates as a well-intentioned energy conservation measure. Ventilation can be used as an interim measure, reducing radon in the short term until the ASD system can be installed and commissioned.

Radon mitigation strategies should factor in installation costs as well as operating costs and reliability. Lowering radon levels in a building requires specific technical knowledge and skills. Health Canada recommends hiring a professional that is certified under the Canadian National Radon Proficiency Program (C-NRPP). Your radon mitigation team should also include individuals who are experienced with commercial buildings and have mechanical system and energy efficiency expertise.

Falcon Engineering is well known for its mechanical, electrical and energy engineering services. Did you know that we also specialize in radon mitigation? We have a mechanical engineer on staff who is a leader in the radon industry and is the only professional engineer who is also a registered C-NRPP Radon Mitigation Professional listed in BC. Along with our team of Mechanical and Energy Engineers, we are well suited to assist you with your radon needs. If you are interested in learning more about radon measurement and mitigation options for your facility, contact us and we can answer all your questions.

Want to learn more about our engineering services? Visit our integrated engineering services page.

Want to learn more about engineering? Check out some of our other blogs!

- Integrating Renewable Energy: A Clean Energy Revolution

- How HVAC Design Can Ensure Comfort and Energy Efficiency

- Dogwood Auditorium: An Innovative Geoexchange Design

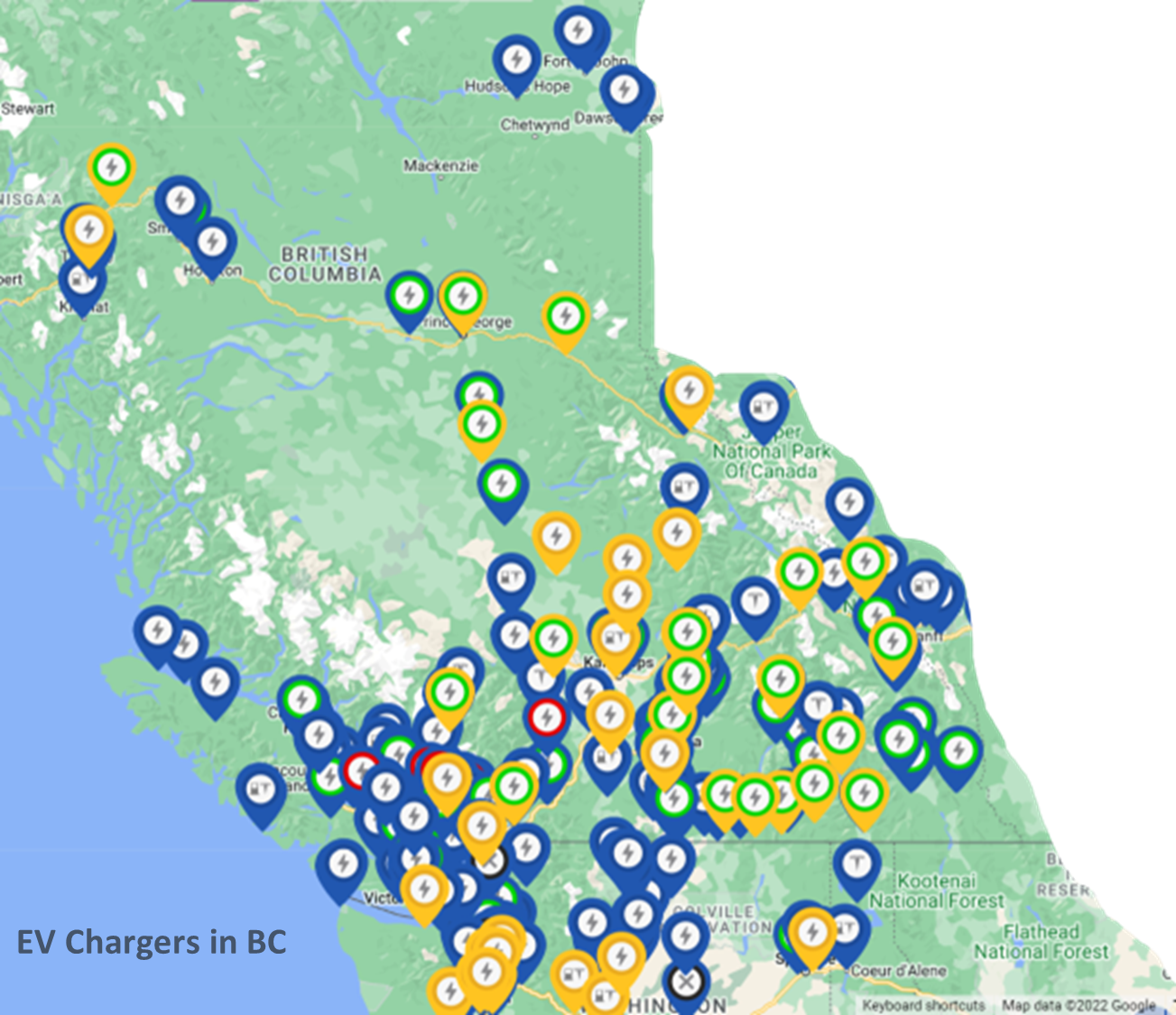

Where does one charge their electric vehicle? Is it at work, at public chargers, at the EV station the traditional gas station has installed? Or is it at home?

The general consensus is that the ideal scenario to facilitate day-to-day driving is that the charging infrastructure would be at home. For longer road trips or heavy-use days, a stop at a DC fast charger would be required. Many people live in single detached homes, however, a growing number of people live in multi-unit residential buildings (MURBs). Let us review the different scenarios (owned vs rental units) and also discuss new construction versus existing buildings.

What Types of Systems Work?

Electric vehicle supply equipment (EVSE) comes in several different sizes (refer to Electrical Vehicle Charging – Part I: The Basics). In a residential environment, Level 2 (AC chargers) of approximately 7.2 KW maximum capacity is the most common EVSE installed. When evaluating average vehicle requirements, one needs to estimate daily driving habits, vehicle efficiency and battery size. The average individual in British Columbia commutes less than 50 km per day. Assuming a vehicle efficiency of approximately 200Wh/km, the daily charging needs of the vehicle would be 10 KWh. With the introduction of trucks and SUVs to the market, the average vehicle efficiency will decrease and the daily charging needs will go up. As an example, let’s use 15KWh daily use. Overnight, vehicles are typically parked for 12 hours. So:

15 KWh ÷ 12 hrs = 1.5 KW

The hourly requirement for charging of only 1.5 KW demonstrates that a Level 1 (standard receptacle) would be enough in most cases. The ability to charge at a higher rate is beneficial when required and Level 2 EVSEs are the expectation both from homeowners and from municipality bylaws (where applicable).

The electrical code requires all EVSE to be taken as a continuous load. This means that unless specific management systems are installed, the total load of EVSE on the electrical system can increase quickly. For a typical 48-unit MURB, if we were to allow for a 7.2 KW EVSE for each unit, it would nearly double the size of incoming electrical service to the building.

Pros and Cons of Suite Fed EVSE and Energy Management System (EMS)

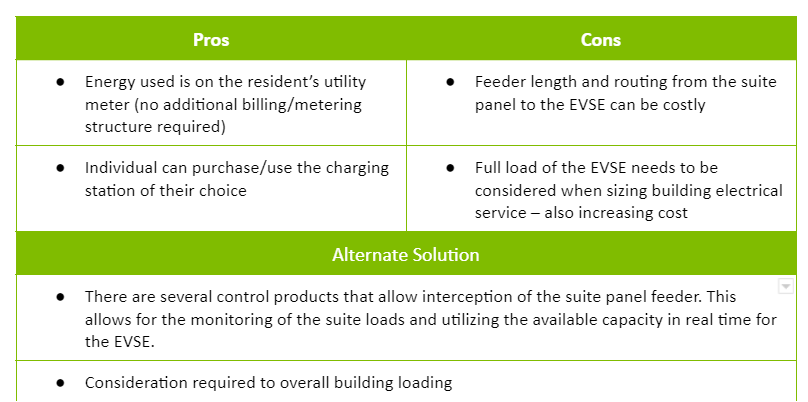

Suite Fed EVSE

For a smaller building where the unit panels are relatively close to the parking stalls, feeding the EVSE directly from the suite panel simplifies installation and billing.

Energy Management System (EMS)

A centrally controlled system that monitors both EV panel and main distribution center capacity and delivers maximum available power to the charging stations. This allows for the building design to incorporate a fixed electrical capacity and distribute it evenly to the charging stations. The power delivered to each charging station depends on how many vehicles are plugged in and require a charge.

I am a Developer – What should I install in my new building?

Municipalities in BC are increasingly adopting specific EV infrastructure Bylaws. The bylaw represents the minimum requirement for any new construction and typically requires at least the rough-in for a charging station at one parking stall per residential unit. Early in the design process of a new building, it is imperative that the bylaw requirements are reviewed and the proper considerations are made regarding the electrical service size and the distribution method.

Market Condominiums – The expectation for new buyers is that there is either infrastructure at the parking stall, or the building is adequately set up to accommodate the addition of EV chargers when required. For small buildings, the suite-fed EVSE option should be considered. For larger buildings (typically more than 20 units), if the intent is to provide an EVSE to each parking stall, the best option is likely an energy-managed system. Consideration for individual owners’ EVSE equipment choices should be made. How integrate different chargers into the distribution system may be difficult.

Rental Apartments – Expectations are not where renters are banking on access to EVSEs, however, it is currently seen as a marketable feature. Since the renter turnover might be more frequent, it is beneficial to have everything installed and controlled by the property manager. If the intent is to install only a couple of units, then it is possible to feed the EVSEs from an EV panel, as the total load would not be a concern to the building distribution system. Property managers have the ability to re-assign parking stalls (not able to with condos) and there is the possibility to simply add a flat rate to the rental cost for the use of the EVSE. If done properly, this system can be expanded in the future to develop into a full EMS. If the intent right away is to install a large number of EVSEs (or maybe a full build-out), then a complete EMS should be considered..

I am a Property Manager/Strata Member – What should I install in my existing building?

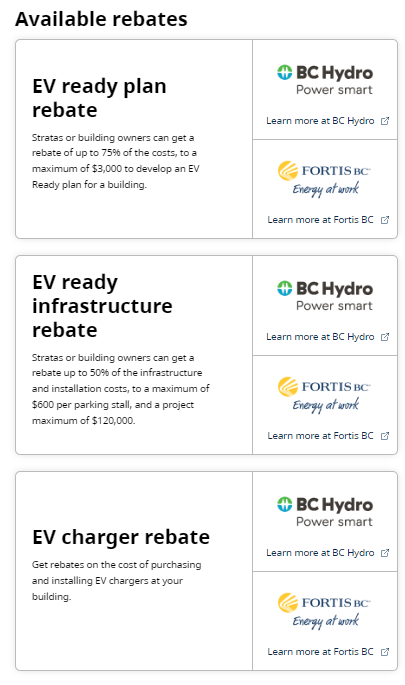

Currently both BC Hydro and FortisBC are working in conjunction with CleanBC to provide incentives for existing buildings to install EV charging infrastructure. The program supports both the engineering costs for an EV Ready Plan report as well as incentives for the installation of conduit, wire and energy management equipment.

The process begins with an evaluation of the building’s electrical infrastructure, as well as historical utility invoices, to determine the capacity of the building and the feasibility of getting the feeders to the required locations. The plan also provides a design that an electrical contractor can use to provide a quote for the required work.

The CleanBC incentives require at minimum that conduit and wire be installed to at least one parking stall per residential unit. The head end management system equipment also needs to be installed, leaving only the final EVSE to be installed when required.

Due to the high likelihood of the building having limited capacity for electric vehicle charging, the installation of an energy management system is in most cases going to be the best solution.

Interested In Installing EV Chargers?

Interested in installing EV chargers in your existing building? Or are you a developer looking to include EV chargers in your design? Then get in contact with our Electrical Engineering team and they can answer all your questions.

Need to learn more about our engineering services? Visit our integrated engineering services page.

Want to learn more about electrical engineering? Check out some of our other blogs!

If you think that the design of an HVAC system, utilizing primary energy derived from a geoexchange source, is usually overly complex and is often unsuccessful in reducing energy consumption or Greenhouse Gases emissions, this mechanical design by Falcon Engineering will surprise you!

Introduction

The ‘dream’ of a newly designed public school featuring an affordable HVAC system, with characteristics of very low energy consumption, very low volumes of Greenhouse Gases (GHG) emissions, and which performs consistently and reliably with simple operations and reduced learning curve for operational personnel, is now a reality. Falcon Engineering’s Mechanical Engineering department has achieved that dream, and its latest iteration is constructed within School District 23’s Canyon Falls Middle School in Kelowna, BC. Canyon Falls Middle School was completed in 2019 and, following the lifting of COVID-19 restrictions and protocols, has now performed through a full school educational year operation.

The HVAC system at Canyon Falls needed to meet the School District’s 21st Century Learning Concepts within its mechanical design. It demands that the HVAC system not only serves the ventilation and comfort requirements of each individual classroom, gymnasium, and support spaces, but also must meet the demands imposed by flexible wall structures, larger occupant loads within enlarged spaces, and cooperative learning opportunities (classes melded temporarily to cooperate in lessons and experiences).

Additionally, School District 23 required the HVAC engineering design to meet the Province of BC’s carbon emissions goals, resulting in the new school being designed to meet LEED Gold Standards.

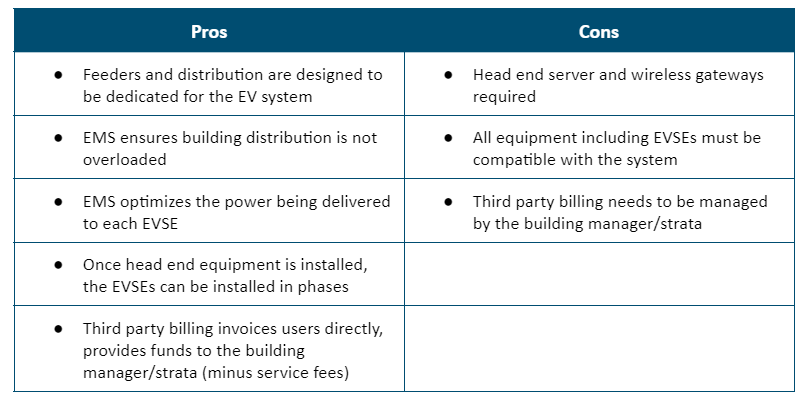

The resultant HVAC design by Falcon’s Mechanical Design Group, led by Andrew Springer, P. Eng., is based on a four-pipe fan coil system, featuring primary energy drawn from a vertical loop geoexchange system, also designed by Falcon. The design of the geoexchange system itself encountered potentially difficult ground conditions, so the Energy Engineering Group at Falcon elected an innovative design concept where a smaller number of deeper boreholes were employed to increase capacity per unit of borehole length.

The HVAC thermal plant design includes the use of a heat recovery chiller featuring unique and custom control sequences designed jointly by Falcon and the equipment manufacturer. This measure reduced the resultant plant complexity and resulted in a system that operates efficiently and without surprises for plant operators and maintainers.

Outdoor air systems feature the use of reversing flow heat recovery equipment, benefitting from efficient waste heat extraction and recovery, as well as the elimination of inherent condensation and icing problems.

Finally, Falcon’s Electrical Engineering design included a complete LED lighting installation, along with addressable lighting controls. The resultant lighting system operates at 35% less consumption than required by Building Code Requirements, and the installed lighting control system offers even greater energy savings in the future. A solar photovoltaic array, installed on the roof of the multipurpose atrium, rounds out the energy-conserving and GHG-avoiding design, to further offset the building’s electricity consumption.

Energy Conservation and GHG Emissions

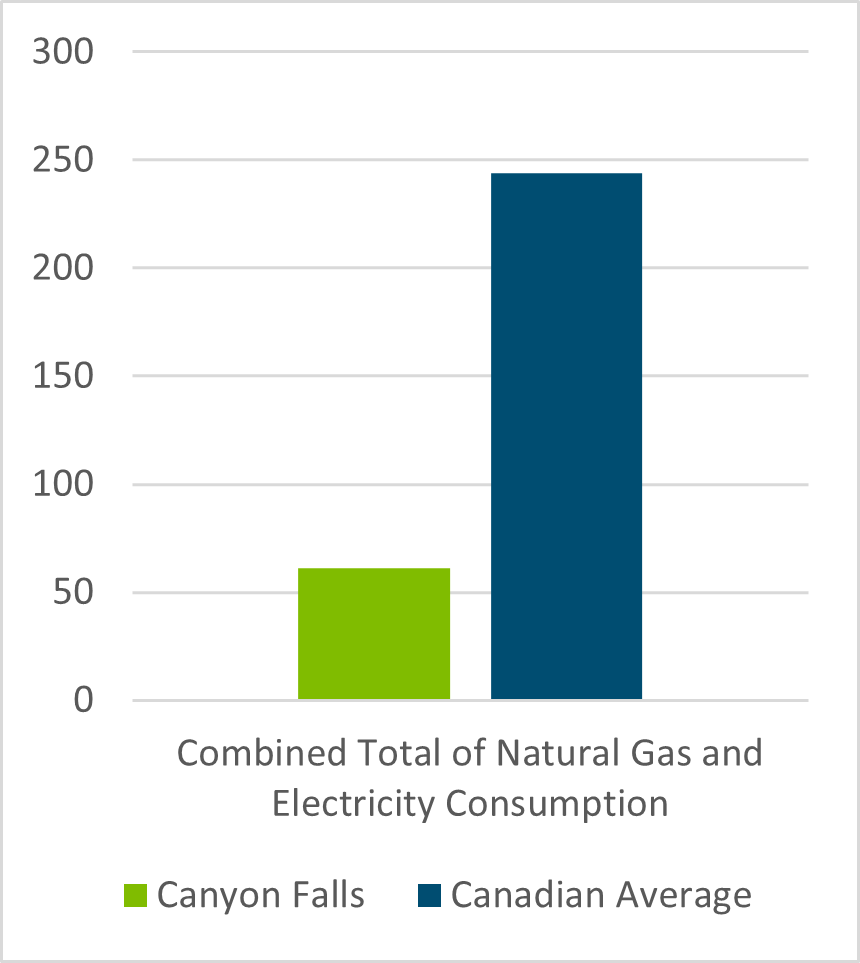

Recently reported Energy Use Intensity (EUI) of Canyon Falls indicates a Building Energy Performance Indicator (BEPI) of 61ekWh/m2yr of the combined total of natural gas and electricity consumption. This figure is well below the Canadian average BEPI of 244ekWh/m2yr for K-12 schools.

Electricity consumption, alone, is reported to be 52 kWh/m2yr which is the lowest in the District, where the District-wide average is 112 kWh/m2yr. This demonstrates, too, that the natural gas component of the total EUI is just 9ekWh/m2yr, largely representing domestic hot water energy consumption, and that performance, in turn, demonstrates the value of deriving the primary energy for the HVAC design from a successful geoexchange system.

GHG emissions are reported at 19 tonnes of CO2e/yr, or 2 kg/m2yr. And compared to School District 23 averages, Canyon Falls’ additional carbon reduction is equivalent to 37 passenger cars off the road each year, or to the planting and growth of 28,700 trees over 10 years.

How the HVAC Design Supports the School District’s 21st-Century Learning Concepts

As HVAC designers and users will well appreciate, designing an HVAC system to meet standard requirements for individual regular classrooms and to also meet the ventilation and comfort (temperature) requirements of a much larger area when flexible walls are moved apart, suggests the use of a complex HVAC system and suggests, also, that occupants might have to tolerate sub-standard performance characteristics in one classroom configuration or another. The flexible walls between classrooms and multi-use areas are integral to the 21st Century Learning Concepts of School District 23, for periodically accommodating larger groups of school children collaborating within the enlarged spaces normally separated by walls.

Not so, with this HVAC engineering design by Falcon! The four-pipe fan coil systems in each classroom, multi-use area, and other occupancies, supports the varying demands imposed by alternate wall configurations, providing reliable and comfortable conditions whether configured in standard classroom configuration, or larger collaboration configurations.

A Reliable and Simple HVAC Design

The installation of the HVAC design by Falcon at Canyon Falls has been described by School District 23 operators and maintainers as easy to understand, easy to maintain, and simple to operate. Utilizing innovations in design, as described above, collaborations with equipment manufacturers, and a purposeful drive for simplicity in design, Falcon has delivered an HVAC engineering design that meets (maybe even exceeds) the needs and expectations of the School District’s system operators and maintainers.

The School District’s Point of View

Mr. Harold Schock, Central Okanagan Public Schools’ Energy & Sustainability Manager, when asked for his opinions on the statements within this blog, had these comments to make:

“[The Province of] BC has legislated targets for reducing greenhouse gas emissions 40% below 2007 levels by 2030, 60% by 2040, and 80% by 2050. The Province also has an interim target to reduce emissions by 16% by 2025. At Canyon Falls Middle School (CFMS), [the design] has performed at the highest level of GHG avoidance. Meeting and exceeding the Provincial challenge of 80% GHG reduction target without adding to the total utility cost.”

Further, Mr. Schock reported that “At CFMS, total energy needed for a full year [of operation] is only 0.40Gj/m2. CFMS has earned an Energy Star Rating of 100% for three years in a row.”

And Mr. Schock ended his comments with the following statement, “Falcon Engineering Team’s primary focus [in the CFMS design] is to move heat energy efficiently. Rather than creating & wasting heat energy.”

Conclusion

Going back to the opening statement of implied complexity of HVAC designs utilizing geoexchange as their primary energy source, Falcon Engineering’s Mechanical Engineering Group has demonstrated at a variety of projects, including Canyon Falls Middle School, that their systems design may be more factually described as “high on the sophistication scale, while low on the complexity scale.” It is this sophistication in design that has resulted in an overall successful consumption-reducing, GHG-avoiding, comfortable and reliable system, designed to be flexible for school occupants and simultaneously easily operated and maintained by School District 23 employees over the lives of the systems within the school. All that, plus energy conservation and Greenhouse Gases emissions reductions, too!

If you would like to find out how we can help with the HVAC design for your project, get in contact by using our contact page.

You can find out more about our Energy Engineering services here and more about our team.

If you have questions about our experience or the HVAC system work we do, get in contact by using our contact page.

Want to learn more about energy engineering? Check out some of our other blogs!

- The Key Benefits Of Heating Systems

- Integrating Renewable Energy: A Clean Energy Revolution

- An Introduction To Geoexchange

An inquisitive, perceptive, and innovative engineering approach by Falcon Engineering helped Royal Roads University avoid unnecessary construction costs, as well as disruptive work, in the design for a geoexchange ground coupling system for the Dogwood Auditorium.

The Project

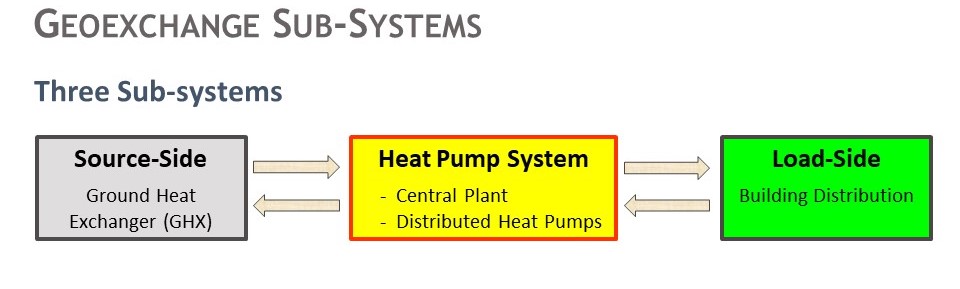

A “geoexchange system” may sound complex, but it is really as simple as its name implies: exchanging “heat” from earth materials or groundwater below the earth’s surface with the building’s HVAC systems, so as to provide heating and cooling energy, all without consuming fossil fuels or adding to the building’s Carbon Emissions. Our blog, An Introduction To Geoexchange, gives an overview of geoexchange engineering systems.

Falcon’s Energy Engineering team has completed just such a project at the Dogwood Auditorium at Royal Roads University, near Victoria BC.

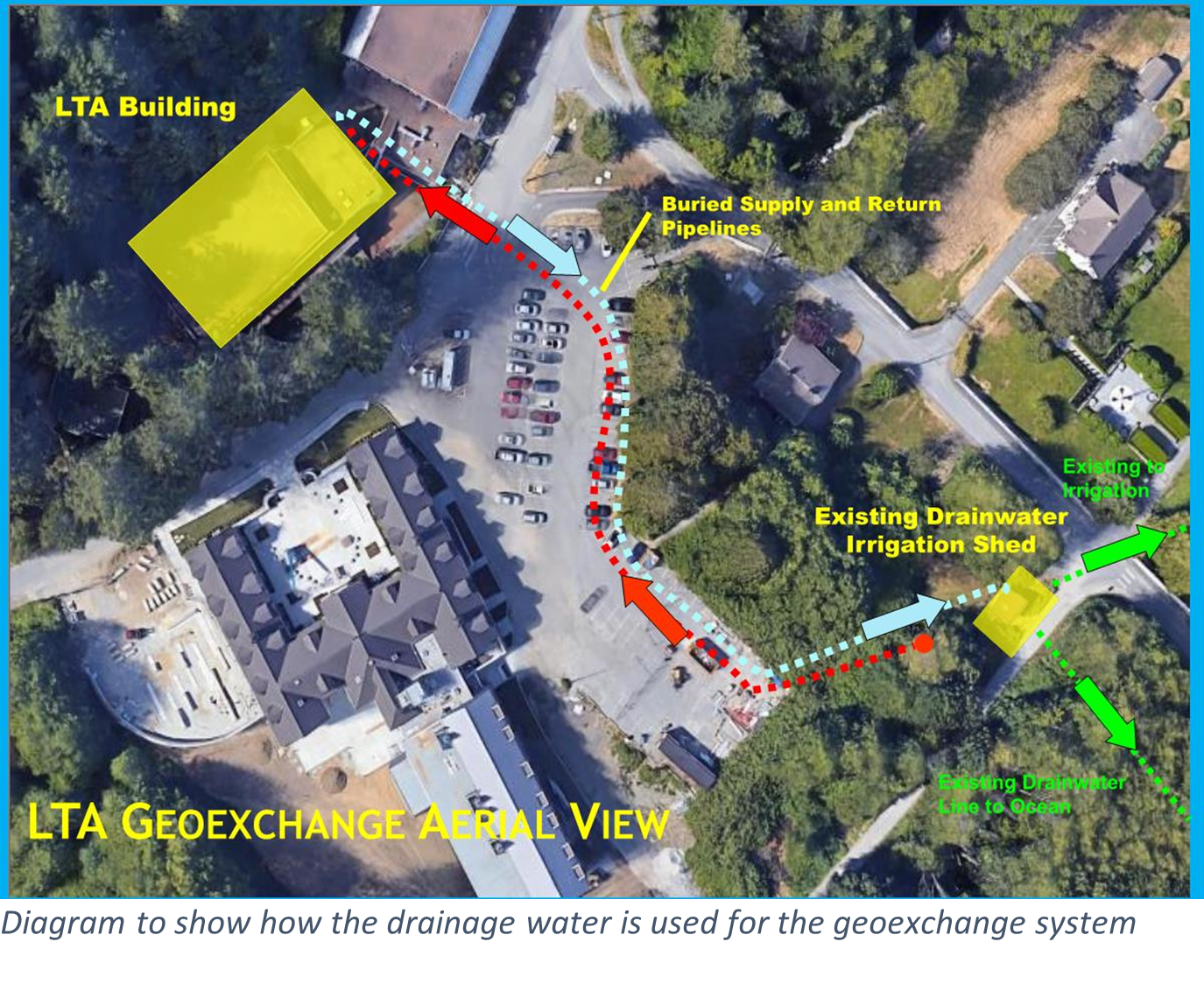

The Royal Roads Campus is situated at the base of a prominent escarpment slope. Areas on campus along the base of the slope have high water tables and, in some areas of the Royal Roads campus, footing interceptor drains are required to control shallow groundwater to protect buildings and infrastructure. Water intercepted by these drains throughout the year is collected and conveyed by pipeline as stormwater discharge. Several years ago, the campus irrigation system was outfitted to use water from the interceptor drains as the main source of water for grounds irrigation to make beneficial use of the intercepted water.

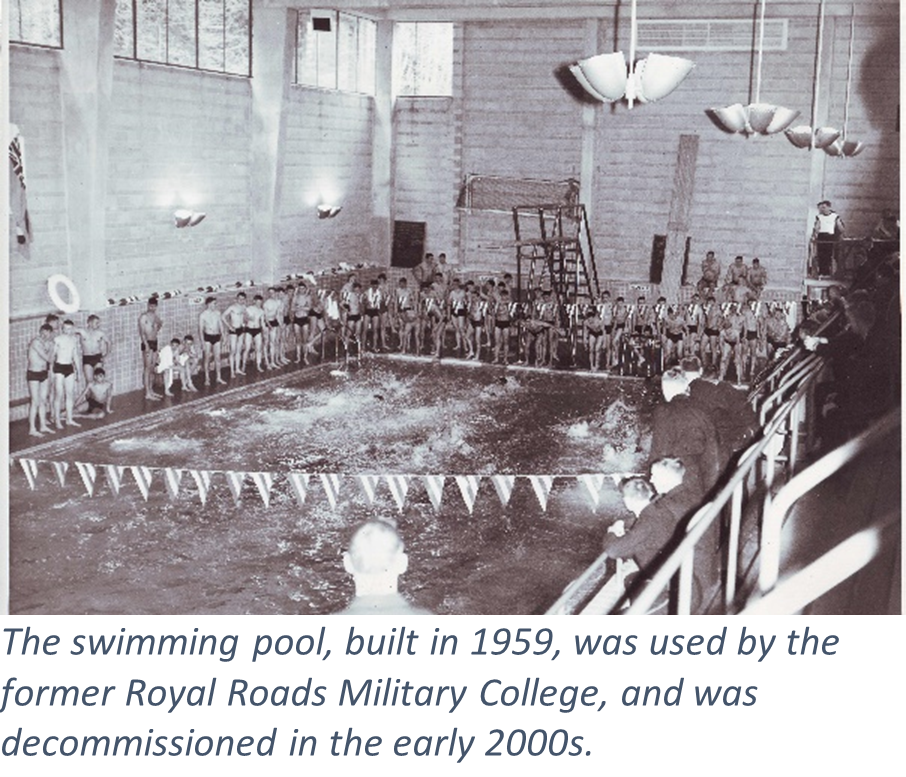

When a project arose to convert the swimming pool (originally built in the late 1950s for the former military college) to a new purpose, the Royal Roads planners wanted to ensure that reducing carbon emissions was an important component of the project plan and budget.

Royal Roads University selected Falcon’s Energy Engineering team, under a competitive RFP process, to examine the natural setting and propose a solution for an alternate energy system to be applied at the legacy building, repurposed as the Dogwood Auditorium.

The project to regenerate the building for learning and events space was opened in its new format in Spring 2021, including the geoexchange heating and cooling system. The system resulted in significantly reduced Greenhouse Gas (GHG) emissions for the Dogwood Auditorium, while providing the energy for comfort conditions throughout the year, with little reliance (peak heating) on fossil fuel energy.

From a Site Visit to Design of the Innovative Geoexchange System

Falcon was selected to design the new geoexchange ground heat exchange (GHX) system (HVAC design was already awarded to another firm), and in the summer and fall of 2019, conducted a thorough site-specific Geoexchange Suitability Assessment (GSA) to investigate the most suitable geoexchange options for the project site. The initial concept envisioned by Royal Roads University (RRU) included an open-loop water well geoexchange system, whereby groundwater would be pumped from one or more extraction wells from which the groundwater would be passed through a heat exchanger, and subsequently re-injected to the ground by one or more injection wells.

However, through the process of conducting the GSA, Falcon became aware of the presence of the significant drain water discharge. Exploratory investigations by Falcon of rushing water in manholes near the prospective Dogwood Auditorium led to the reveal of an existing, readily available energy source, already “plumbed” near the surface.

Falcon conducted further investigations and analysis to establish that the drainage water would be of sufficient flow quantity, and at a satisfactory temperature throughout a given year, before committing to the client that the drainage water would serve as a suitable and reliable ground source coupling for the geoexchange system.

Data from Environment Canada of seasonal climate norms over a period of approximately 30 years was critical to the analysis. Flow rates of the drainage water were measured over the spring and summer of 2019 and added to anecdotal information from the RRU Operators of the irrigation system. Together, these data sets were applied to a calculated “stress test” to ascertain the values of the drain water system as a source of energy to moderate indoor temperatures of the Dogwood Auditorium, as well as to ascertain the likely impacts of the “heat rejection” back into the drain water system during each of the four seasons. The combined analysis demonstrated that this drain water system could be relied upon as an appropriate energy source for heating and cooling the Dogwood Auditorium, and that heat rejection from the Dogwood Auditorium would not deleteriously affect the adjacent ocean water temperatures, to which the drain water from RRU flows.

Thus, Falcon was able to demonstrate the values of the proposed ground source coupling to the geoexchange system and was also able to demonstrate that the environmental impacts of using the ground source coupling (the drain water system) would not impose undesirable impacts (such as excessively warm temperatures) on the drain water or the ocean water.

With any type of retrofit or repurposing project, unexpected findings and conditions are prone to be discovered and this project was no exception. Although the intercepted groundwater-derived drain water had been used for many years by the irrigation system without any history of debris or sedimentation problems, new flows were recently added to the drain water system that included contributions from rooftop drainage. In many geographic locations, rooftop drainage would not pose significant problems; however, on the heavily treed RRU campus, rooftop drainage can be laden with organic debris. In this case, organic debris in the form of evergreen needles and other organics, entered the drain water system from the new sources and contributed to maintenance concerns for both the existing irrigation system and the new geoexchange system. A simple screen and diversion modification was implemented by the Project Civil Engineer in Fall 2021 and seems to be working effectively. Ongoing monitoring is warranted and perhaps additional modifications may be required.

An Energy Efficient Building System

The portion of the heating load served by ground source heat pumps for the Geoexchange System, employing energy derived from the flows of the drain water system existing on campus, results in a 98% reduction in emitted CO2e as compared to the “base case” of standard naturally aspirated boiler and standard air handling systems (commonly found in buildings of that age and utility).

Combined with the relatively low costs of drawing energy from the existing groundwater drainage system, when compared to employing a drilled well system and open or closed loop geoexchange system piping, the resultant system provided the client with:

- a lower capital cost

- very low energy consumption characteristics in operation

- very low GHG emissions,

- and comfortable conditions throughout the year.

A win for the client, a credit to the design engineers and installation contractors, and a credit to the institution (Royal Roads University) who commissioned the project.

Aligning with the Royal Roads University Climate Action Plan

The project to repurpose the former swimming pool at RRU into what is now known as the Dogwood Auditorium reflects the best in contemporary construction and facilities planning. As the Royal Roads University Climate Action Plan calls for significant GHG reductions by 2035, it was seen by University planners as an important aspect of the new use of this existing building that it would not add to the University’s GHG emissions, while simultaneously providing a much-needed events and learning space for the campus.

Consequently, as the geoexchange system delivers on the heating and cooling needs of the Dogwood Auditorium, it does not add CO2e liabilities for RRU, and provides modern ventilation and comfort conditions even when fully occupied by Convocation Ceremonies, University staff meetings, student study areas, and community events.

From an Aged Facility to a State-of-the-Art Auditorium

Royal Roads University and Durwest Construction set out with a vision to repurpose an aged facility and transform it into a state-of-the art auditorium. The level of innovation and commitment to sustainable transformation is a remarkable and defining feature of the redevelopment project. Re-purposing of the drain water, that would otherwise have been wasted, into an energy source seemed to mesh well within the vision of this type of transformation.

As a standard of practice at Falcon Engineering, we emphasize the importance for careful consideration of both the setting- and the building-specific features of a project, to thoroughly examine opportunities for development of a low carbon energy system. In the case of the geoexchange ground coupling at RRU Dogwood Auditorium, this standard of practice ensured that the opportunities inherent in the existing drain water system were recognized early in the investigation process, and subsequently led to an affordable and successful geoexchange system to serve the Dogwood Auditorium. Falcon Engineering feels honoured to have played a role on this team.

You can find out more about our Energy Engineering services here and more about our team.

If you have questions about our experience or the geoexchange work we do, get in contact by using our contact page.

Want to learn more about energy engineering? Check out some of our other blogs!

- The Key Benefits Of Heating Systems

- Integrating Renewable Energy: A Clean Energy Revolution

- An Introduction To Geoexchange

By Loïc Letailleur, P.Eng.

Four years ago, we used to play a game as a family while driving around – who could spot the next electric car? They were rare and sometimes you would go days without seeing one. Now, they are everywhere, every day, no matter which city or small town you are in. Most people likely don’t realize how many there are because they don’t all stand out (they aren’t just Tesla’s)!

With the rapid adoption of electric vehicles comes the requirement for charging infrastructure. There are charging speeds (is the limiter of the vehicle or the charger), people’s driving habits and also public expectations. Without getting into the psychology of range anxiety or other concerns, let’s review some of the key points related to electric vehicle (EV) charging.

What are the different levels of Electric Vehicle Charging?

At Falcon, we provide capital planning services for all types of buildings. As a unique engineering firm, we have developed a proprietary costing database. We regularly update this database with our retrofit projects to provide new and existing clients with a detailed capital plan for their upcoming projects. We are even able to break budgets into project phases for comprehensive planning purposes.

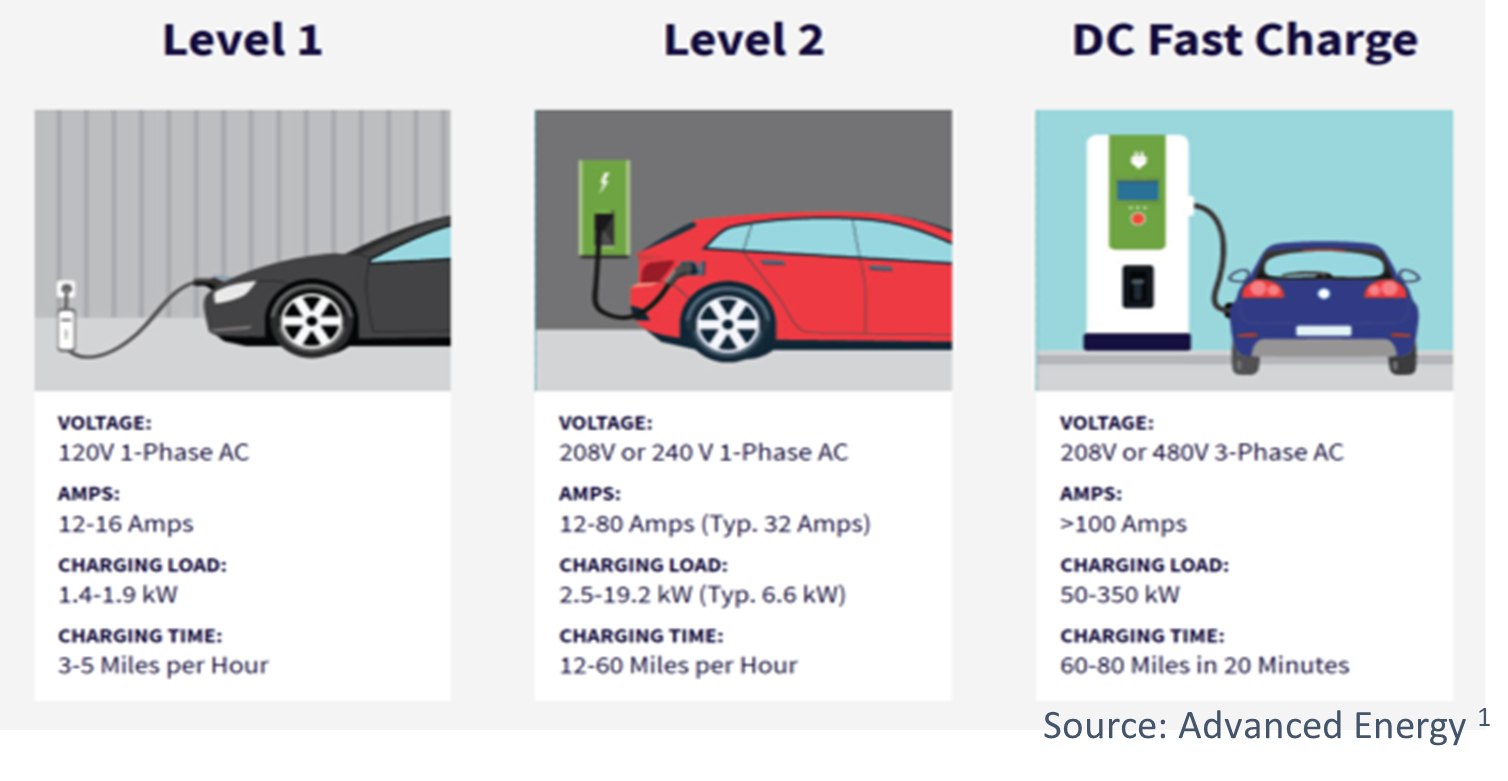

- Level 1 – Basic 120V wall outlet (15 or 20 Amp)

- This will charge the average EV at approximately 8km/hr.

- Level 2 – AC charger, 208/240V from 15A to 80A of delivered energy

- This will charge the average EV at 15-80km/hr.

- Level 3 – DC fast charger, from 20KW to 350KW

- This can reach charging speeds over 1,000km/hr.

- It bypasses the inverter in the vehicle.

- Vehicles have limits to what they can accept for charge (not many can take 350KW).

What are the Electric Vehicle Charging Standards and how do they differ?

There is one Level 2 charging standard globally and it is the J1772 plug. All vehicles have this outlet except for Tesla, which comes with an adapter.

Globally, there are three major Level 3 charging standards:

- Tesla – Proprietary charger plug except in the EU. The Supercharger network in the USA is slated to be opened to other vehicles, though this will require a special adapter.

- Chademo – Asian standard, was adopted early by Nissan – many fast chargers will include a Chademo connector. Not many vehicles require this standard.

- CCS – European standard, has become the global standard. It is the plug included in the majority of vehicles (except Tesla).

When assessing which charging level you will most frequently use, you need to assess the following factors:

- What is your daily distance travelled?

- Do you have access to charging at your residence? And what level?

The majority of individuals will drive less than 50 km per day, and their vehicle is parked for a minimum of 8 hrs overnight. This means for those fortunate enough to have access to charging at home, a simple Level 1 charger that will provide 8km/hr (60+ km of range overnight) is sufficient.

A Level 2 charger at home will allow for more rapid charging or allow for the charging to occur during off-peak hours (maybe not start charging until 0100 – with a time of day utility billing coming soon this may be advantageous). On the rare occasion that you have returned from a long road trip with a nearly empty battery, you still don’t need to worry as overnight you will charge enough for the next typical driving day. If back-to-back extended trips are required, then a visit to a public Level 3 charger is an easy way to boost up the available range.

For individuals who do not have access to charging at their home, Level 3 charging will be similar to stopping at the gas station and will have to be done approximately once a week depending on the range of the car and the distances covered.

What about at Work?

One of the most frequent questions we are asked by Clients is should electric vehicle charging be provided at the workplace? To answer this, it is important to go back to the previous analysis of daily driving habits. If individuals have access to charging, then it would be rare that needing to charge at the workplace (or the mall) would be required. Even for people without home access to charging, the rapid increase in the number of public fast charging stations allows for easy access to charging needs people may have. I would consider the availability of workplace charging a perk and not a necessity.

The exception to this is for fleet vehicles.

I am a Developer and What Should I Do?

In Part II of Electrical Vehicle Charging our engineering team will discuss the options for both existing and new multi-family and mixed-use buildings.

Do you have any questions? Contact our skilled engineering team today and we can answer all your electrical engineering questions.

Need to learn more about our engineering services? Visit our integrated engineering services page.

Want to learn more about electrical engineering? Check out some of our other blogs!

- Integrating Renewable Energy: A Clean Energy Revolution

- Becoming Climate Neutral Certified

- The Benefits Of Solar Panels

Are you wondering how to get the right retrofit for your project?

Our team of interdisciplinary engineers can provide customized niche mechanical engineering solutions for projects ranging from HVAC design to deep energy retrofits. Our team has a proven track record of results on these projects and are well versed in requirements for different client types. We bring a commitment to service that extends through design, construction, and post-construction activities.

Read on as we elaborate on some of our niche mechanical and industrial engineering services that set us apart from other engineering companies:

Capital Planning

At Falcon, we provide capital planning services for all types of buildings. As a unique engineering firm, we have developed a proprietary costing database. We regularly update this database with our retrofit projects to provide new and existing clients with a detailed capital plan for their upcoming projects. We are even able to break budgets into project phases for comprehensive planning purposes.

Design

Design is an integral part of the engineering and construction phase of your project. We are experienced with tailoring bespoke solutions that best suit

the need of your project’s purpose and building type. Some of our niche design services include:

Lifecycle-Centered Design. Building and engineering represent only a fraction of the overall lifecycle costs of a mechanical project. With this in mind, we take an approach that is not focused solely on the installation costs of a project. We include operating cost considerations like energy efficiency, ease of maintenance, reliability, and planning for replacements at the end of service life. Our lifecycle-centered design approach applies to all our projects.

Heat Pump Thermal Plant Design. We have developed several bespoke heat pump and heat recovery thermal plant designs. These archetypal systems can be adapted and modified to fit the needs of many building types and configurations. The systems have been designed to eliminate unnecessary complexity, undue costs, and to reduce the maintenance burden.

Retrofits

We know that every project has a specific purpose with distinct needs to suit the environment in which it operates. We have expertise in planning, managing, and implementing large-scale mechanical retrofits. We offer retrofits in the following areas:

Deep Energy Retrofits. The goal of deep energy retrofits is to provide systems that not only increase energy efficiency but also renew aging equipment to improve overall effectiveness and reliability. Often this involves the replacement of major components and systems. These retrofits often need to be carefully planned and phased in to keep the facility as operational as possible throughout the process

Conventional Energy Retrofits. If you don’t need a large-scale retrofit, our team is also able to replace building mechanical systems on a component-by-component basis. These could consist of boiler upgrades, terminal equipment replacement, and control system upgrades. We replace aging equipment or systems to optimize lifecycle costs and reliability.

Prime Consulting. Having worked with both private and public institutions, we are experienced in consulting on contract awards for facility upgrades or new system implementation. Depending on the project, we can provide full design services as well as managing tendering, providing recommendations for contract award, and administering the construction contract throughout the implementation phase. Our experience with many different building types makes us well versed in the different requirements for all client types.

Industrial and Clean Facilities

At Falcon, we have developed specialist expertise for industrial buildings. From ventilation systems to specialty water system design, our team will develop the right solution for your facility. Some of our specialized areas include:

- Precision environmental control

- Clean-room filtration and contaminant control

- Laboratory ventilation

- Specialty exhaust and ventilation systems

- Specialty process piping systems

- Compressed air system design

- Process heating and cooling

- Process water system design

Is it time for a retrofit for your facility or building?

We are confident that our team will deliver designs that will add the right components to your facilities’ systems to increase reliability and efficiency. Our engineering professionals are seasoned experts, who know how to create and implement a lifecycle-centered approach to your system upgrade. You can guarantee practical and innovative solutions, designed for your specific needs.

Have questions about a project? Contact us!

Need to learn more about our services? Visit our integrated services page.

Want to learn more about mechanical engineering? Check out some of our other blogs!

- Benefits Of Troubleshooting Your HVAC System

- Elements Of A Fire Sprinkler System

- 6 Ways To Make Your Classroom More Comfortable During Highly Variable Temperatures

What are Solar Photovoltaic Systems?

A solar photovoltaic (PV) system is a composition of one or more solar panels combined with an inverter and other electrical and mechanical systems. Photons, which are packets of light from the sun, fall onto solar panels and create electric currents called photovoltaic effect.

Choosing these energy efficient options has advantages that are beneficial to both your return on investment and your environmental impact. The following article will cover some of the benefits we have seen from projects.

Environmental Longevity

Solar PV systems have long life cycles and low production costs while helping to reduce the consumption of energy.

One of our projects at the Nicola Valley Institute of Technology in Merritt, British Columbia, highlights the energy that can be saved by choosing the installation of solar PV systems.

The system consists of 30 KW of installed rooftop panels. The gym roof comprises production panels with fixed racking, while the lower teaching roof consists of 4 rows of panels at different tilt angles, including one row with the ability to rotate the azimuth (angle reference to South) to allow students the ability to monitor the effects each installation variation has on overall production. Each of the demonstration rows is separately monitored in the system. Since its installation in 2018, the system has generated over 105 MWh of energy and has saved more than 41 Tons in CO2 emissions.

Read more about this project

Low Maintenance

Solar PV panels are also very low maintenance. Panels are constructed to be robust and withstand all types of weather conditions such as heavy snow, wind, sleet, and hail. Regions with high winds may require clearing of dust, but the burden is insignificant.

Easily Installed Anywhere

These systems can be virtually installed anywhere. At the Canyon Falls Middle School project in Kelowna, British Columbia, the panels were installed on the school’s rooftop. From rooftops to fields, these systems can be optimized to catch the right amount of energy and generate it into electricity to power schools, hospitals, multi-family residences and office buildings.

Return on Investment

One example to illustrate the return on investment of solar PV systems is the project at Naghtanqed School, a remote school in Nemiah Valley, British Columbia.

The goal of this project was to reduce the fuel usage and carbon footprint of the school.

This solar PV system consists of 50kW Photovoltaic panels and 108 kWHr of battery storage, which generates 137,000 kWh of electricity per year.

The estimated payback of the project is only 7.5 years, with fuel savings estimated at over 38,000 litres per year.

With PV solar systems you can expect savings from low maintenance, energy consumption optimization, and off-setting utility bills. Solar PV will be integral to the movement towards the electrification of building systems.

Are you ready for an energy-efficient system?

From schools to office buildings, solar PV is a cost-effective solution in reducing your environmental footprint while achieving better energy consumption and maximizing savings.

At Falcon Engineering we are ready to leverage our skilled electrical teams to design the perfect Photovoltaic system, optimized for your needs.

Want to talk about your project? Contact us!

Want to learn more about energy engineering? Check out some of our other blogs!

The adoption of newer and more efficient technologies is constantly changing. In the 20th century we saw this happen with oil and gas furnaces replacing coal, as they provided a cleaner and more efficient alternative for heating. Today, the transition to even cleaner heating system solutions is occurring. The demand for heat pumps, electric heaters, geoexchange and more, have increased substantially, with the aim to efficiently heat buildings while producing less carbon emissions. It’s important to understand how these new heating technologies work, and how they can benefit the right space.

Whether you are looking for heating systems in a home, public building, or industrial facility, in this blog we go through different heating system alternatives – and help build the understanding for future heating and cooling needs.

Integrated technology applications

Integrated technology applications combine energy applications in a way that leverages the benefits of different technologies (for example solar and geoexchange). It is important to consider how various energy technologies, such as HVAC systems, lighting, and envelope systems, will be integrated into the overall project. The key link in integrated technology is building design focused on energy use. This results in cost savings with strong energy optimization.

Air source heat pump systems

Heat pumps are the future of heating and cooling. Air pumps don’t burn fuel to heat a building but rather extract heat from the air and concentrate it for use within the building. Air source heat pumps are roughly 2 to 3 times more efficient than burning fossil fuels, such as oil or natural gas, to generate heat.

Geoexchange heat pump systems

We broke down the concepts of geothermal heating before in a previous blog. However, to briefly explain the concept, geoexchange efficiently heats and cools buildings using energy extracted from the ground using heat pumps. What makes this heating system ideal are the results. In many applications, well-designed geoexchange systems can nearly or fully eliminate carbon emissions associated with building heating and cooling.

Geoexchange systems run on electricity and can replace your conventional heating system, avoiding the emissions that come from burning fuel.

Ground source heat pumps extract heat from the ground and are one of the most efficient ways to heat your home.

“In fact, they can reduce utility bills by 70 percent over conventional systems, and they’re extremely reliable, with in-ground components that can last 50 years” (Sense, 2020). While they do have a high installation cost, they are also incredibly reliable systems.

The team at Falcon Engineering was able to assist with mechanical design for Crawford Bay Elementary-Secondary School back in 2009.

This project included a ground source heat pump which provided extensive heat recovery opportunities. Our engineering team worked with this client to provide a long-term heating solution.

Conclusion

At Falcon Engineering, we have the experience to give our clients low carbon energy strategies to help guide their decision-making today, for achieving compatibility with tomorrow’s expectations. Our engineering services allow us to evolve with changing technologies to give our clients the best heating system solutions.

Learn more about our previous heating system projects here.

Want to learn more about energy engineering? Check out some of our other blogs!

- The Benefits Of Solar Panels

- Integrating Renewable Energy: A Clean Energy Revolution

- An Introduction To Geoexchange

References:

https://blog.sense.com/how-to-choose-your-next-heating-system

https://www.thisoldhouse.com/heating-cooling/21014980/geothermal-heat-pump-how-it-works