Aging fire protection systems can be subject to catastrophic failures which require emergency funding. Constant monitoring, inspections, and proper maintenance can provide advanced warning of system problems, so that any upgrades needed can be initiated in a thoughtful and careful manner at a reduced capital cost.

Engineering analysis will help guide the process of deciding whether to allocate capital funds for replacement or continue with the current maintenance program.

As we established in our earlier blog Elements of a Fire Sprinkler System, there are a number of different sprinkler systems, including wet and dry systems. Dry systems don’t contain water and are pressurized with air, while wet systems have pipes filled with pressurized water at all times. Both systems can experience issues as they age.

Below, we discuss the top 11 items to look for with aging sprinkler systems:

1. Inspection Testing and Maintenance

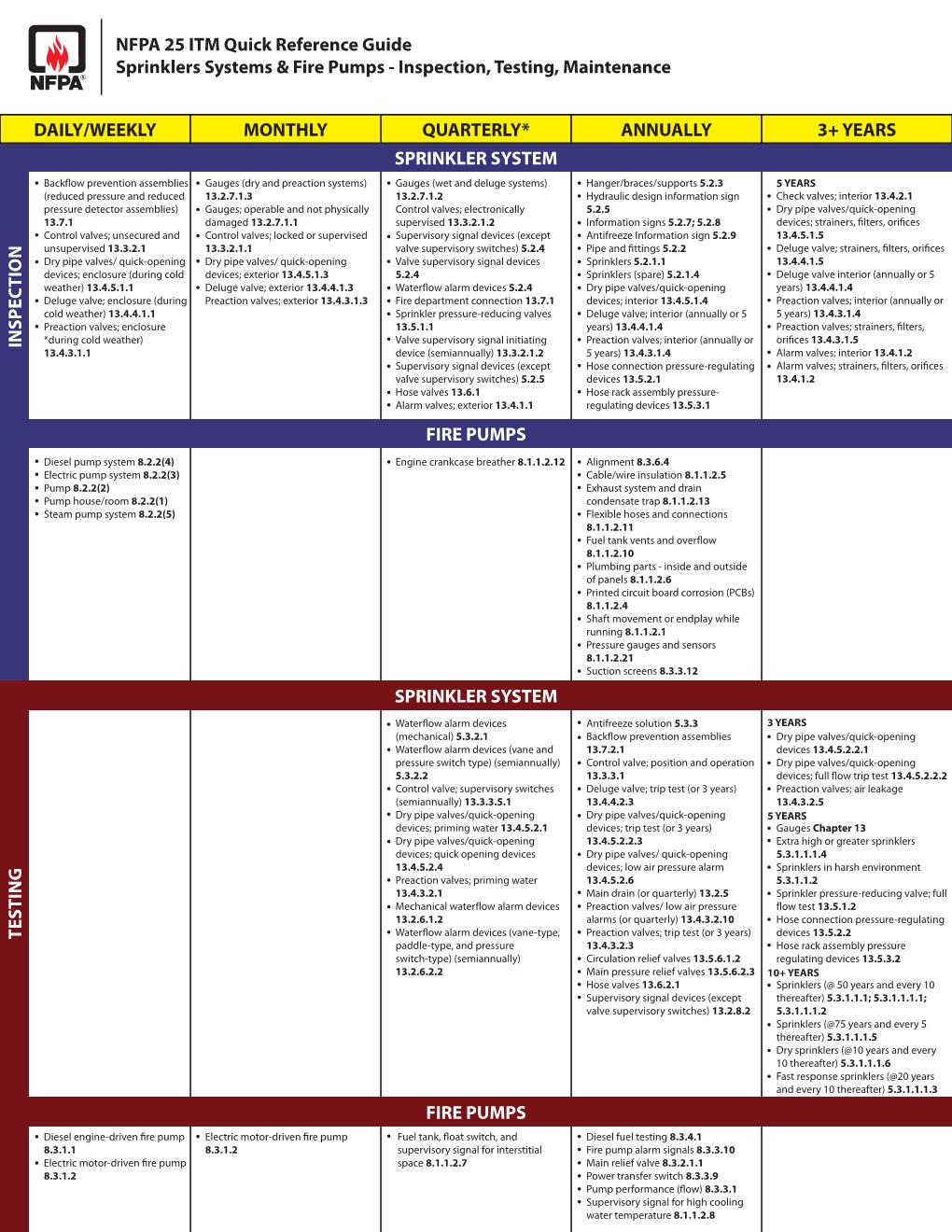

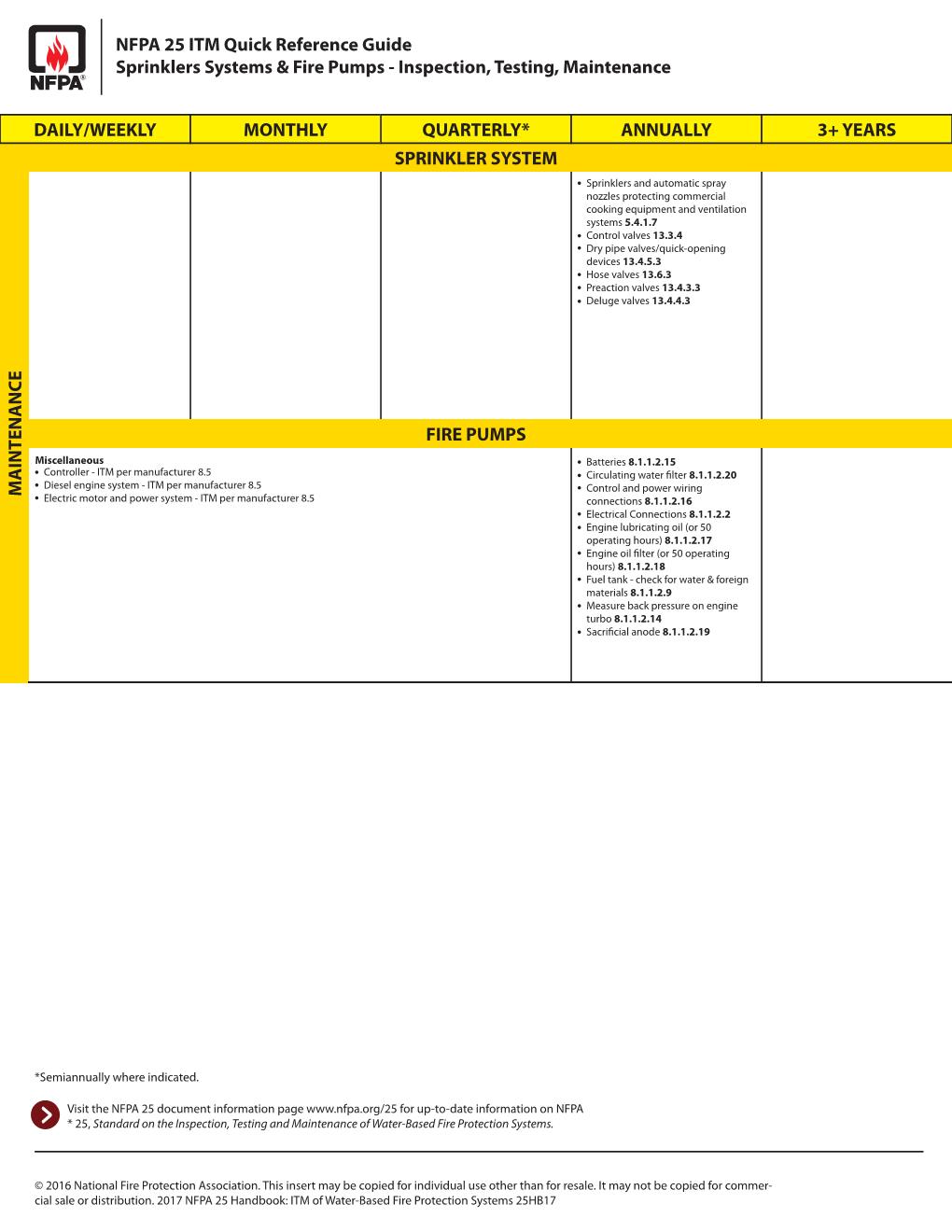

The National Fire Protection Association (NFPA) 25 standard governs the inspection, testing and maintenance of water-based fire suppression systems, and gives timelines for what should be covered in quarterly, semi-annual, annual, three-year and five-year inspections. The required inspection reports should be completed by a competent and careful service provider as required by NFPA 25. The NFPA 25 chart is included at the end of this blog.

2. Dry Systems

Typically, dry systems degrade much faster than wet systems due to increased levels of oxygen, and require special care and attention, especially for systems that are older than 20 years which may be nearing the end of their service life. In unusual circumstances, we have seen dry system pipes fail in as little as 2 years. Additional measures, such as the introduction of nitrogen into dry systems, can extend a dry system’s life expectancy considerably.

3. Leaks Developing in Pipe

Keep an eye out for external seepage. Pipes rust from the inside out, so if you can see signs of seepage on pin holes or threads, you will need to react quickly.

4. Dry System Air Compressor Runs Continuously

A dry system air compressor should only run every 2 or 3 days. If it runs more often, you have leaks. One of the biggest problems is that as more compressed air enters the pipe, more moisture and oxygen is introduced, and so more corrosion occurs. It is a vicious cycle.

5. Recalled Sprinkler Heads

Many sprinkler heads manufactured by Central were recalled in 2002 because the seal would stay plugged which wouldn’t allow water through when activated. This could result in the loss of a building if there was a fire. We still see these heads in facilities, together with many other heads that have also been recalled. Visual inspections by a trained eye are the best solution.

6. Renovations without Checking System Design

Alterations to a sprinkler system may stop the system from operating properly with the city water pressure. Simply adding or relocating one sprinkler head in the design area could place the owner at risk if the system is not compliant with NFPA 13. NFPA 13 is the standard for the installation of sprinkler systems, which provides minimum requirements for the design and installation of automatic fire sprinkler systems and exposure protection sprinkler systems.

7. Destructively Tested

Sprinkler heads need to be destructively tested to be compliant with NFPA 13. This test is conducted by an approved laboratory to ensure a representative sample of the sprinkler heads installed will activate properly when heated to the listing temperature. At the end of the service lengths listed below, four heads of each style need to be removed and tested:

50 years – Standard Heads

20 years – Quick Response

10 years – Dry Heads

If a single head fails, all similar heads on site will require replacement.

8. Know How to Turn Off a Sprinkler Zone in an Emergency

In the event of an accidental discharge through a sprinkler head or a broken sprinkler pipe, the quick identification and location of important sprinkler valves will mitigate the potential for significant water damage.

9. Building Envelope

We have seen a lot of building envelope issues that have led to wet sprinkler pipe freezing. The sprinkler heads can pop or the pipes break during cold weather spells. When the water in the sprinkler system thaws, the water flows can be significant, and trigger unexpected facility evacuations. Recent renovations completed in the summer are a common source of these events.

10. Drain Maintenance

If dry systems are drained of water in the fall before the cold season, then the potential for the sprinkler pipe freezing is minimal. If it takes a long time to drain a system, the rust inside the pipe might be retaining water and slowing down the process. This may indicate a requirement for an internal inspection.

11. Water Sequence Entry Pipe Comes Apart

We have seen some services that use galvanized or plated rods in a high water table, which accelerate the corrosion on the threads, and come apart with catastrophic flooding. Modern practices using stainless steel rods and better thrust blocks help to improve reliability and longevity.

Conclusion

Throwing good money at a bad system is not typically the best long term solution. 35 years for a wet system and 25 years for a dry system is a common life expectancy. But the reality is that the life expectancy will depend on the water chemistry, materials used in the system, and a proper maintenance program.

The NFPA 25 chart below lists the minimum required frequency for inspection, testing and maintenance activities.

At Falcon Engineering, we can help with identifying any potential issues with aging sprinkler systems and work with our clients to find solutions. If you have any questions about how our team can help you with your mechanical projects, including fire sprinkler engineering, get in contact by using our contact page.

Want to learn more about our engineering services? Visit our mechanical engineering services page.

Want to learn more about engineering? Check out some of our other blogs!